Characteristics and applications of PA66

PA66, or polyamide 66, is an engineering plastic that is widely used in many fields due to its excellent mechanical properties and heat resistance. The following is a detailed introduction to the characteristics, applications, injection molding defects and solutions of PA66.

Features of PA66 :

•High strength and rigidity: PA66 has high tensile strength and rigidity, allowing it to withstand high loads and resist deformation.

•Heat resistance: PA66 has a high heat distortion temperature, usually between 160-180°C, and is suitable for applications in high temperature environments.

•Wear resistance: PA66 has good wear resistance and is suitable for manufacturing bearings, gears and other parts that require wear resistance.

•Chemical stability: PA66 shows good resistance to most greases, solvents and chemicals, and is suitable for use in chemical environments.

•Processability: PA66 is easy to injection mold and can be processed through traditional thermoplastic processing methods.

Application of PA66 :

•Automotive industry: PA66 is used to manufacture automotive parts, such as hoods, dashboards, doors, seat structures, etc., providing sufficient strength and heat resistance.

•Electronic and electrical appliances: In the field of electronic and electrical appliances, PA66 is used to manufacture connectors, coils, electrical switches, etc. because of its excellent electrical insulation properties.

•Mechanical parts: PA66 is used to manufacture various mechanical parts, such as gears, bearings, pump parts, etc., due to its wear resistance and impact resistance.

•Sports equipment: PA66 is also used in the manufacture of sports equipment, such as bicycle parts, ski equipment, etc., due to its light weight and high strength.

Injection molding defects and solutions :

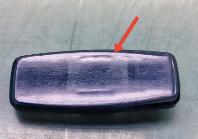

•Shrinkage and dents: caused by uneven cooling and shrinkage of the material. Solutions include optimizing injection molding parameters (such as mold temperature, injection pressure and speed), using a more appropriate cooling system, or adjusting product design to reduce wall thickness differences.

•Warpage: PA66 injection molded parts may experience warpage, especially reinforced materials. The solution is to adjust the injection molding process parameters, such as increasing the mold temperature and injection cycle, or adding mineral fillers or amorphous materials to the material formula to reduce uneven shrinkage caused by crystallization.

•Floating fiber: Glass fiber reinforced PA66 may have problems with surface fibers being exposed. Solutions include increasing the injection temperature and mold temperature, adjusting the injection speed and pressure, or adding compatibilizers and dispersants to the material.

•Mold fouling: caused by excessive small molecule content or poor thermal stability of the material. The solution is to reduce the amount of small molecule additives, improve the thermal stability of PA66, or use polymer additives.

The following is a description of possible image captions: