PEEK innovation gear material

As a precise, efficient, safe and reliable transmission mode, gear transmission has been widely used in various fields. Its working principle mainly depends on the teeth on the wheel rim, which transmits the movement through the continuous engagement between the two gears. This characteristic of continuous operation requires that the material of the gear must have sufficient strength and hardness, while the surface needs to be smooth to reduce friction and wear. Metal materials are widely used because of their hardness and strength, but with the development of technology, PEEK material gear is gradually valued due to its excellent wear resistance, fatigue resistance and self-lubricity.

In modern industry, the role of the gear is very important, whether it is the transmission system, the steering system, the liquid delivery system, the performance of the gear directly affects the efficiency, stability and durability of the whole system. However, the traditional metal gear in the processing process has large processing error, high cost, installation difficulty, long manufacturing cycle and other problems, and easy to produce large friction noise and easy to damage in daily use. Therefore, looking for high-performance gear materials has become a major trend in the development of the major industries.

PEEK (polyether ether ketone) is a high performance engineering plastic with many advantages of traditional metal materials. The wear resistance and lightweight of PEEK materials are excellent, which allows the gears made from PEEK to have minimal loss in long-term use, thus significantly reducing maintenance costs. In addition, the PEEK gear is lubricated without additional lubricant, which not only reduces the complexity of maintenance, but also improves the reliability of the system.

PEEK material has gradually attracted more and more attention because of its excellent properties. PEEK gears have the following significant advantages:

high-wearing feature

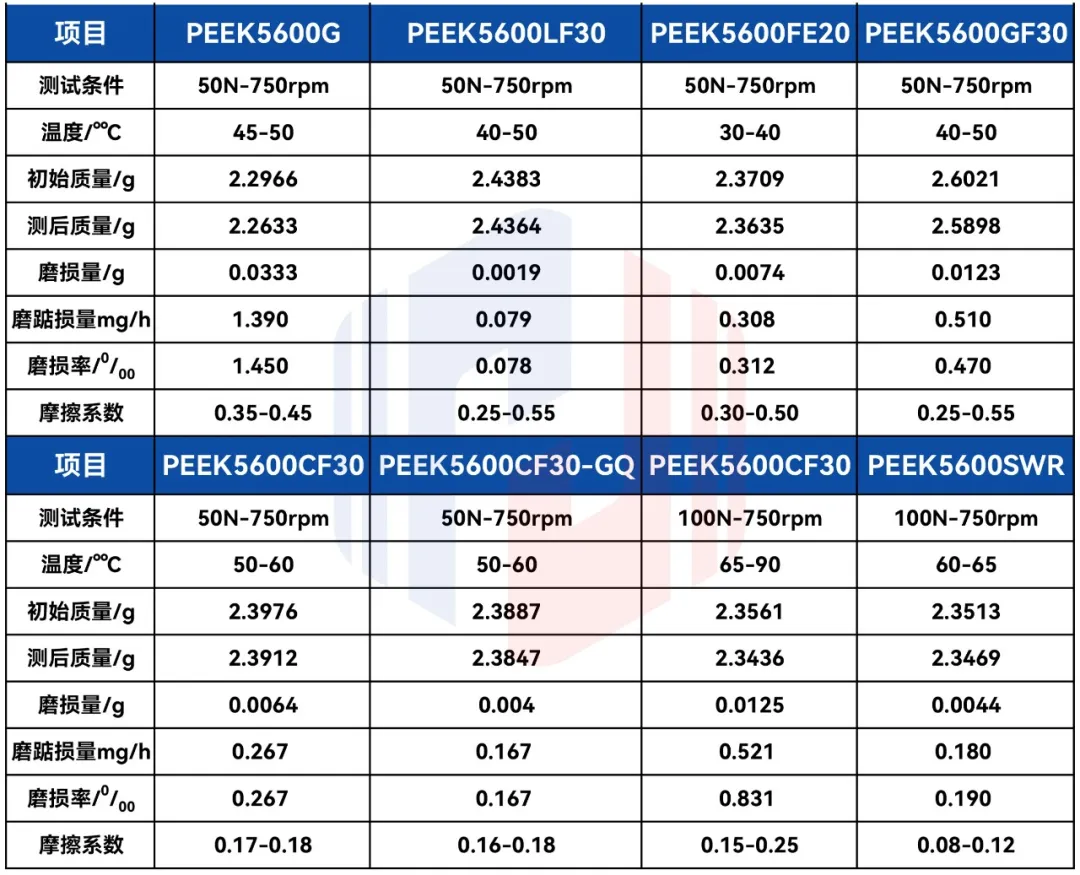

PEEK stands out in gear applications with its excellent high wear resistance, not only showing excellent self-lubrication characteristics, but also can maintain a low wear rate in various environments. Even in the face of harsh conditions up to 260MPa, its sliding resistance and rolling wear ability is still not reduced, ensuring the stability and reliability of long-term use.

In order to further meet the stringent demand of high-speed and high-load components, Junhua carefully launched PEEK5600SWR particles and their products, with wear resistance as low as half of PEEK5600CF30, providing a more lasting and not easy to break solution for high-load components, and ensuring the long-term efficient operation of the equipment.

High strength

PEEK material stands out for its excellent strength characteristics, and its performance index significantly exceeds POM. Even in high temperature environment, PEEK can still maintain excellent mechanical properties. After PEEK5600CF30 with carbon fiber composite modification, the tensile strength reaches 230MPa, which is 2 times that of pure PEEK.

On this basis, PEEK5600CF30-GQ high strength particles and products were developed, which not only inherited the original advantages of PEEK5600CF30 in high temperature resistance, corrosion resistance and friction resistance, but also achieved a higher tensile strength of 260MPa, 15% higher than PEEK5600CF30, becoming an ideal choice for high stress components such as isolation sleeve for magnetic pump.

self-lubrication

With its excellent self-lubrication characteristics, PEEK material significantly reduces the degree of friction and wear, thus reducing unnecessary energy loss and noise pollution, effectively extends the service life of gear and other transmission components, and greatly reduces the cost of subsequent maintenance. The PEEK gear can form a stable transfer film at the moment of friction with the dual gear. Even when the transfer film gradually adapts to the stable friction state, it can maintain the stability of the film, so as to ensure the stability of the friction coefficient and the very low level of wear rate.

In addition, PEEK gear also significantly reduces the potential pollution of lubricating oil to the product. Compared with the traditional metal gear, its operation is more quiet and more durable, which provides strong support for the stable operation of all kinds of mechanical systems.

corrosion resistance

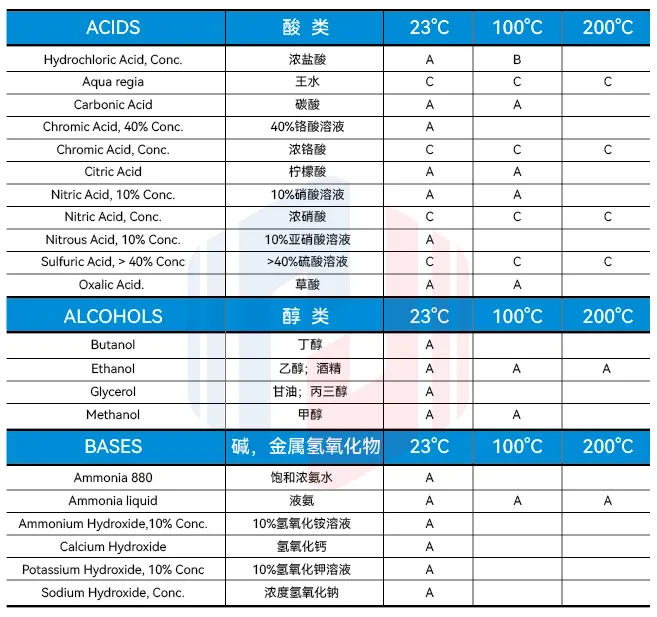

PEEK shows excellent chemical stability, showing extraordinary resistance to a wide range of organic solvents, oils, weak acids and weak bases. In addition to concentrated sulfuric acid, PEEK is almost insoluble in any other acid and base solutions and organic solvents. Its corrosion resistance is comparable to that of nickel steel.

Not only that, PEEK also has very low water absorption characteristics, under 23℃ saturation rate is only 0.5%, this feature ensures its stability and reliability in wet environment, its excellent heat water resistance is better, even in up to 260℃ of pressurized hot water or steam environment, PEEK can still maintain its excellent performance, fully demonstrate its unique advantages as a special engineering material.

light weight

PEEK material stands out with its ultra-low density (only 1.3) and is significantly lighter than traditional commonly used metal materials. The gear made of PEEK material achieves significant weight reduction compared to the metal gear. This lightweight advantage not only helps to reduce the overall load and inertia of the entire equipment, but also directly reduces the rotational inertia, thus improving the torque weight ratio and torque inertia ratio, making the equipment show more excellent performance in response speed, power transmission efficiency and overall energy consumption control.

In addition to the excellent characteristics mentioned above, PEEK material also ensures the stability and reliability of PEEK gear components under extreme working conditions, significantly extending the service life. Therefore, PEEK materials are widely used in many industries, and have become an indispensable key material to improve the equipment performance and ensure the safety of operation.

With the promotion of industrial upgrading and domestic substitution, China's PEEK gear market is growing, which puts forward higher requirements for materials, not only to reduce the cost, but also to improve performance and efficiency, reduce weight and achieve miniaturization. The emergence of PEEK materials is an ideal choice to meet these challenges. It not only meets the high performance requirements of future systems, but also brings new possibilities for the development of gear transmission technology.